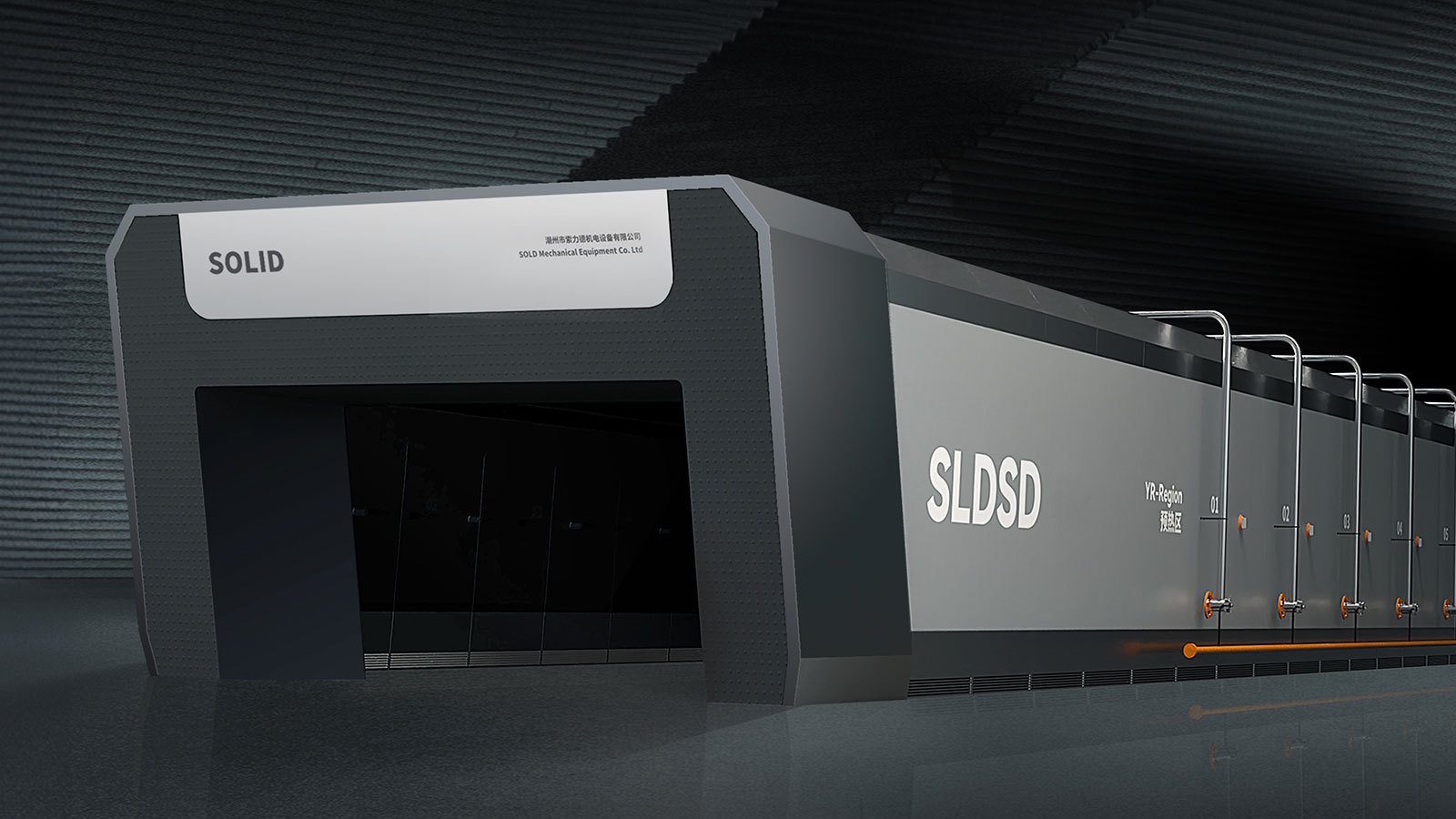

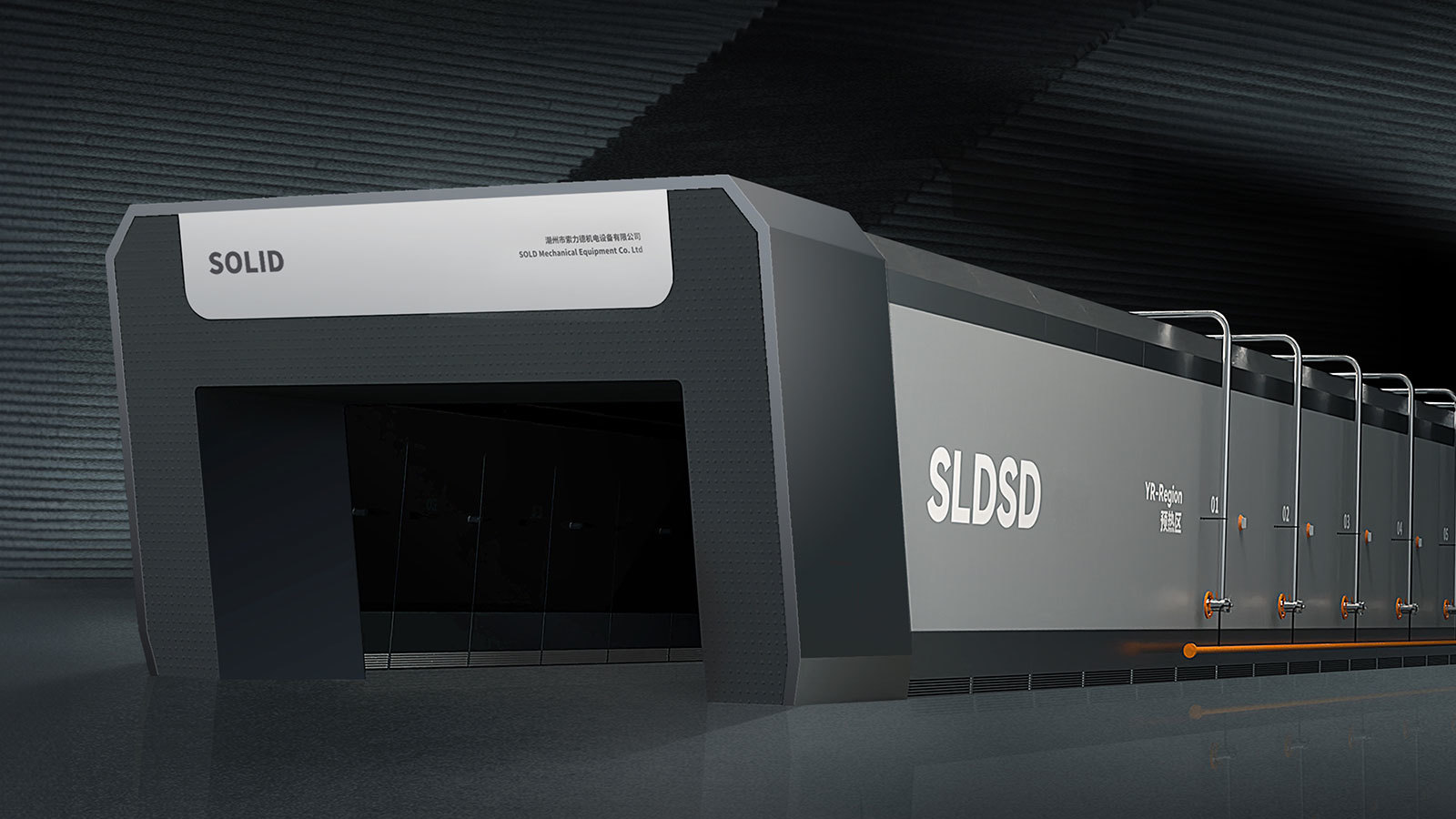

About Us

Energy-saving kiln furnace customization expert

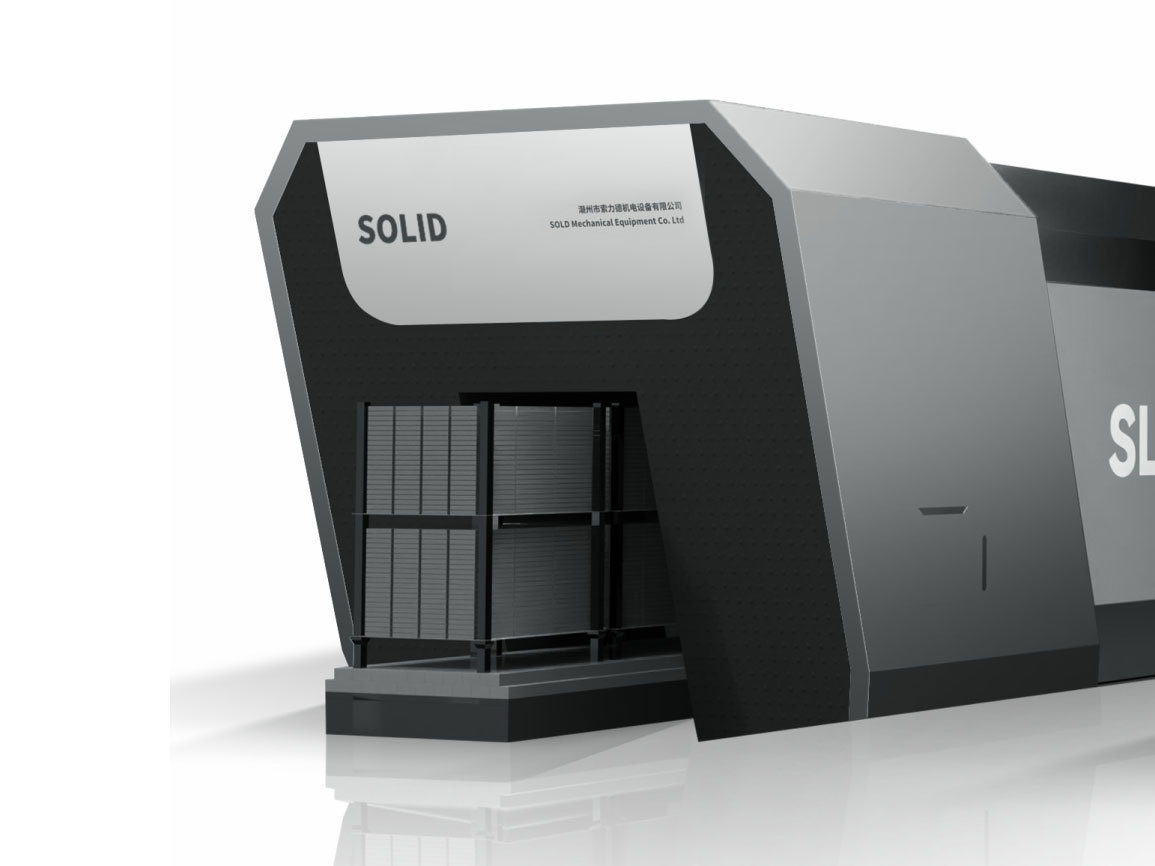

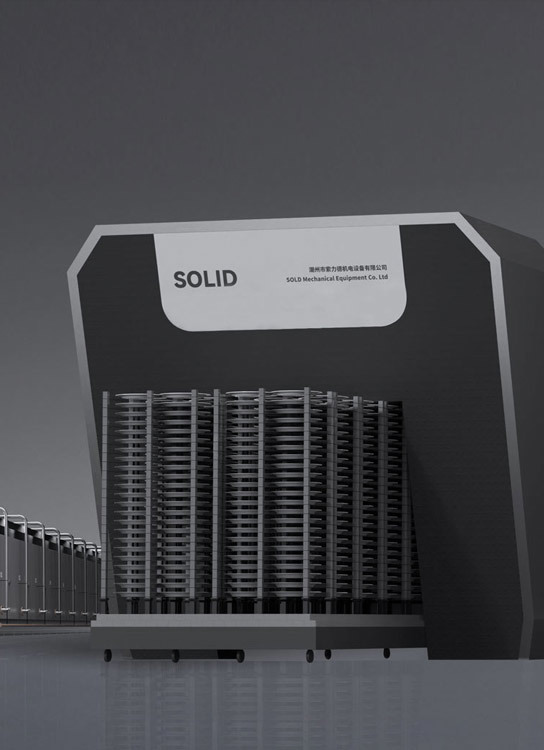

Chaozhou Solid Electromechanical Equipment Co., Ltd.

Company establishment time

More than 30 years of technical experience

Deep Partners

Export to multiple countries

More than ten patents

Product Center

Focus on the research, design and installation of gas ceramic kilns

Company Chronicles

ENTERPRISE CHRONICLES

Application Areas

Tailor-made industry solutions

News

Focus on real-time corporate dynamics, publish new authoritative information, and learn more about Solid.

News | Guangdong's first natural gas hydrogen-doped ceramic shuttle kiln ignited successfully

November 2024, with the igniter started, the kiln instantly lit a roaring flame, Guangdong's first ceramic shuttle kiln natural gas doping hydrogen combustion test research science and technology project in Chaozhou officially run successfully, for the traditional ceramic industry green transformation and process innovation to lay a solid foundation.

Heat transfer characteristics of shuttle kilns

In a flame kiln, the combustion products transfer heat to the product through convection and radiation. 1) Convection: The temperature difference between the flue gas and the product is proportional to the 0.8th power of the flue gas velocity in the kiln...

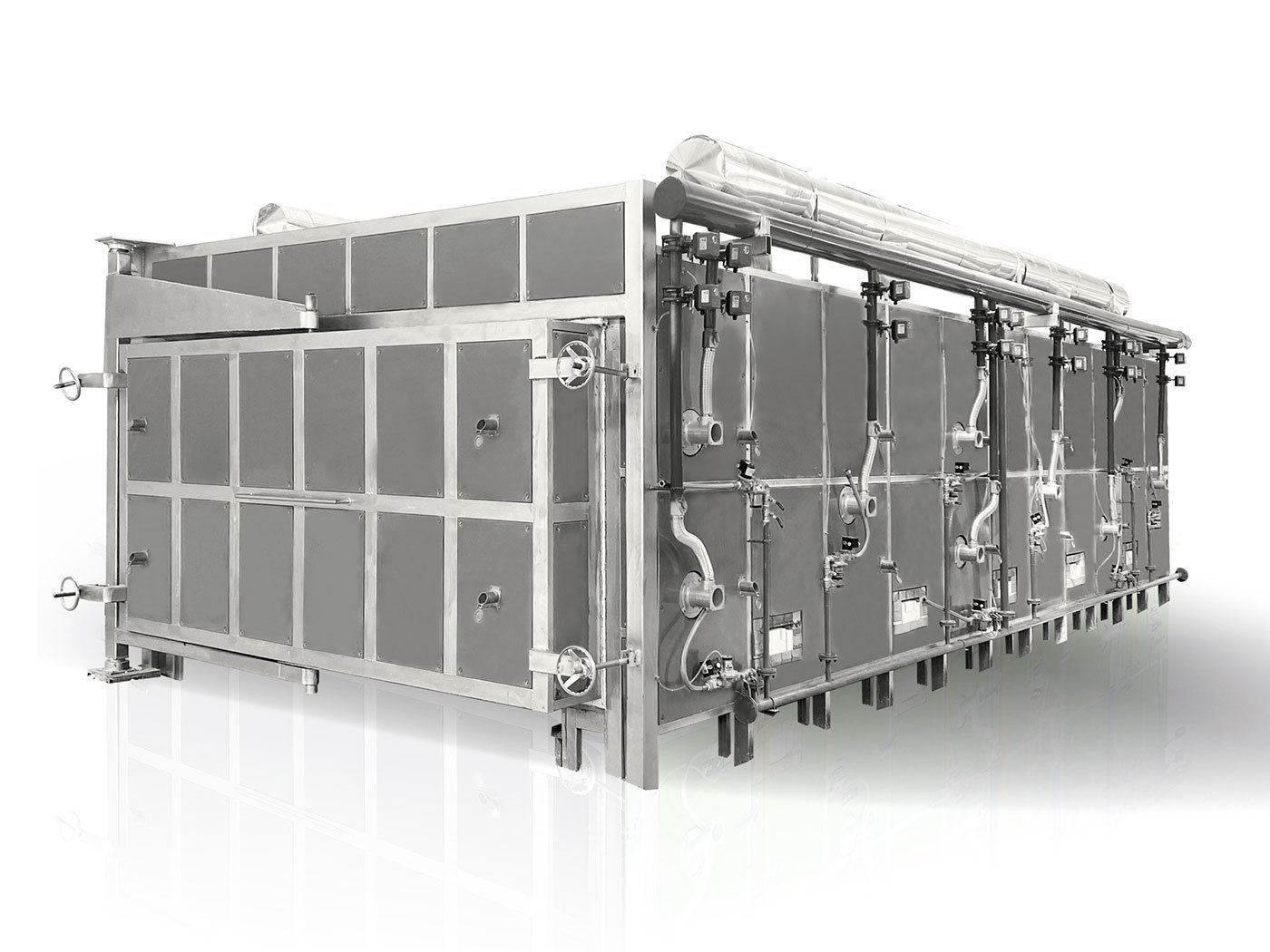

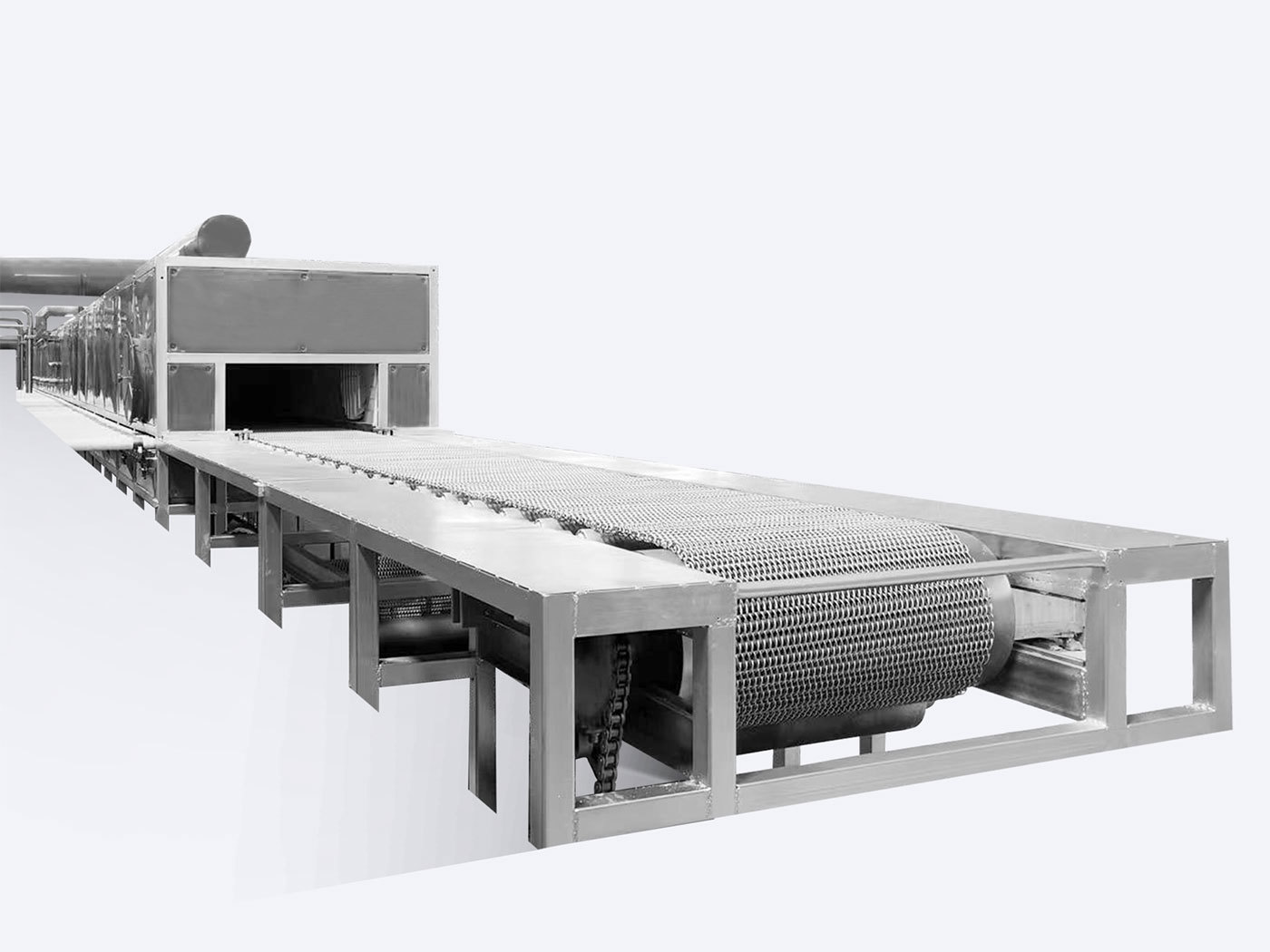

Tunnel kilns have various different classifications

1. Classified by firing temperature: (1) Low-temperature tunnel kiln (1000~1350℃); (2) Medium-temperature tunnel kiln (1350~1550...

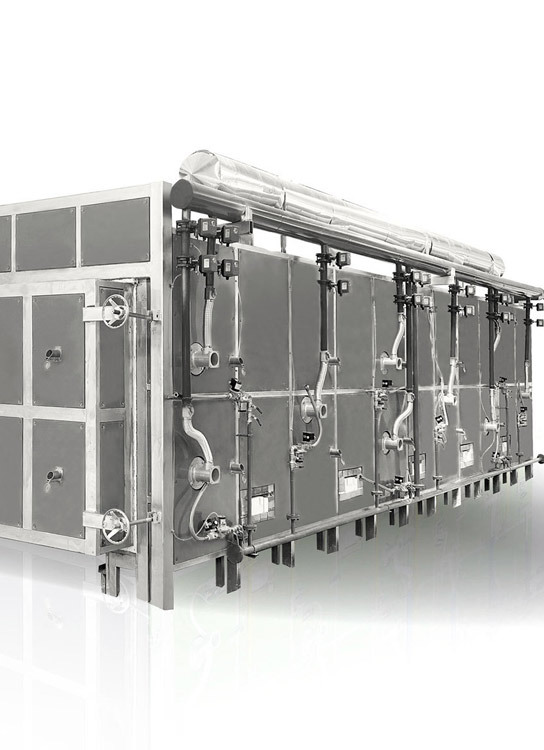

The structural composition of a shuttle kiln

Shuttle kiln: This is an intermittent firing kiln, similar in structure to a matchbox. The kiln car is pushed into the kiln for firing, and then pulled out in the opposite direction after firing to unload the fired ceramics. The kiln car is like a shuttle, hence the name shuttle kiln. Shuttle kilns are thermal equipment for intermittent production with a kiln car as the kiln bottom and a downdraft (or semi-downdraft) flame. They are also called car-bottom downdraft kilns, or drawer kilns because the kiln car enters and exits from one end of the kiln. They are one of the fastest-developing kiln types in China in recent ten years. In addition to the advantages of general downdraft kilns, such as great operational flexibility and the ability to meet multi-variety production, shuttle kilns allow loading, unloading, and partial cooling of the products to be carried out outside the kiln. This improves working conditions and shortens the kiln's turnover time. However, due to intermittent firing, the kiln has large heat storage and heat dissipation losses, high flue gas temperature, and high heat consumption. New energy-saving shuttle kilns have improved the kiln body masonry structure and added waste gas heat recovery devices, greatly improving this shortcoming.

How to choose a ceramic kiln

1. For daily production less than 20 cubic meters, with multiple product types and varying firing temperatures, and whose output is insufficient for a tunnel kiln, a fast-firing shuttle kiln is recommended. 2. For daily production equal to or greater than 20 cubic meters, but with complex glazes such as kiln-change crystal glazes requiring a certain constant temperature and cooling time, a traditional shuttle kiln or electric shuttle kiln can be used; if kiln-change or crystal glazes are only partial, a fast kiln can be selected. Fast kilns are not only fast, but can also be slowed down. Slow firing allows for very small temperature differences. However, slow firing has poor energy efficiency. 3. For large-scale production, high height, heavy weight, high temperature, and single glaze, a roller hearth tunnel kiln can be selected. For example, high-temperature daily-use ceramics and sanitary ware. 4. For temperatures below 1300℃, and large-scale production of art ceramics, daily-use ceramics, and sanitary ware, a roller kiln or a large fast shuttle kiln is recommended.

Matters needing attention when re-igniting the kiln

After a period of inactivity, the kiln has gradually cooled down, and the system parameters on the kiln have gradually changed to a state that needs to be reset. At this time, although the kiln's state parameters are different from those of a new kiln, they are already in a "zero" state. When using the kiln again, it needs to be reignited. So what should be paid attention to when reigniting? Different kilns should be handled differently.